|

INSPECTION & PREVENTIVE MAINTENANCE SERVICE

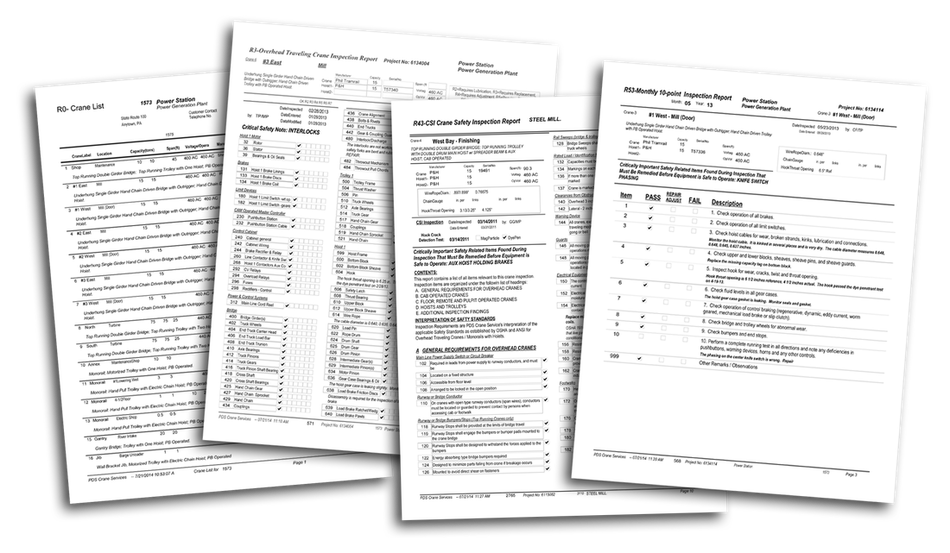

Current Safety Standards require that all overhead cranes in regular use be inspected and maintained and that records of the inspection be kept on file. All of our inspectors have been trained and certified by the Crane Institute of America and are up-to-date with the latest revision of the Overhead Crane Safety Standards. PDS Crane Service offers an Inspection Program with Documentation to assist your facility with meeting these requirements. Specifically, we offer the following types of inspections:

|

A Program of Preventive Maintenance in conjunction with an inspection program will reduce overall repair costs, frequency of repair and unexpected downtime. Often a simple adjustment done in a timely manner can prevent destruction of components which can result in untimely and very costly repairs. The Preventive Maintenance Program that we offer in conjunction with our Inspection Program includes:

|